Step 1. Ingredient selection and testing.

A product is only as good as the ingredients that are selected. This in my opinion is where many products sometimes fall short of the mark with regard to efficacy. Part of the reason for this is that most consumers are blissfully unaware of the significant differences that there can be between ingredients that seem to be the same!

I'll try and explain this statement a little better. Let's say you are looking at a product and it has grape seed extract in it. Let's also assume that both manufacturers are labelling their products in accordance with US FDA. The label would read “Grape seed extract (Vitis vinifera species – xxmgs”. That is all the label has to say. But, there can be a world of difference between them!

One grape seed extract could be an ethanol extract from *China and may have quite high levels of heavy metals depending upon the extraction method. On the other hand the other grape seed extract may be a water extract from grapes grown and harvested in New Zealand. They both sound the same but the difference is chalk to cheese in the levels of efficacy and purity, (we use only the water based one from New Zealand. *This should not be taken that all ingredients out of China are substandard. That is not the case. As in any other country there are some very good ones, but there are some very bad ones as well. You get what you pay for!)

However, the manufacturer has the ability to decide on the specifications of the ingredient they select. They are permitted to use the lower quality ingredient if they wish, which by the way could be 1/10th of the cost of the more effective ingredient. This may use twice as much which looks good for the consumer but still is only a 1/5th of the cost of the more effective product.

To perhaps illustrate this point even better let's consider Red Grape Skin extract. Normal red grape skin which is full of valuable nutrients is normally produced after the red grapes have been fermented. The skins are white at that stage because the color has been leached out as part of the wine making process and the skins are a by-product.

There are around 20 actives in red grape skin but most red grape skin extracts only contain about 4 actives. Usually an ethanol extract is used.

In contrast the red grape skin extract that we use in our products is a water extracted New Zealand red grape skin which is NOT fermented and is a deep purple color. On analysis the extract is found to contain the exact same active profile as the raw red grape skin (i.e. around 20 actives).

BUT…on the label it reads exactly the same as one of the red grape skin extracts which can be sourced for a fraction of the price. The consumer never knows, and neither do most of the marketers of dietary supplements as they use contract manufacturers and they simply specify an amount of red grape skin extract and they don't appreciate the differences. The contract manufacturers who have to bid for the business use the cheapest material they can.

But it is legal and within FDA GMP guidelines. No one can specify a particular quality of an ingredient in a dietary supplement, just like car manufacturers cannot be forced to make every car to the same quality as a Rolls Royce. At the end of the day it is up to the manufacturer as to what standard they set for their products even though they know most of their customers may never know what their policy is.

OK…I hope I have explained this issue adequately.

So, having determined the quality of the ingredient you want, then the manufacturer under cGMP is required to prove that the ingredient that they are using is indeed the same as the specification that they have determined should be used in that particular product.

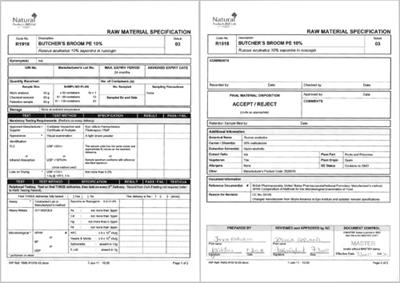

This requires a specification to be prepared for each ingredient. I have posted a copy below of a typical spec. (Natural Products (NZ) Ltd is part of the Xtend-Life group and is our manufacturing operation.)

INGREDIENT SPECIFICATION

You will see the specification covers not only the microbiological and heavy metal tests but also full identification and assay testing. We also specify the carrier to be used in the extract…and all these ingredients do have carriers.

Oh, here are some photographs of our QA (Quality Assurance) office with some of our staff.

PHOTO OF THE RAW INGREDIENTS BEING WHEELED INTO THE TESTING AREA

Next a technician from the QA dept takes samples of each ingredient in the sampling booth. The container of ingredient then stored remains in the secure quarantine area and cannot be used until it passes all the following steps.

PHOTO OF A STAFF MEMBER TAKING THE SAMPLES

Multiple samples are then sent to specialist accredited labs:

- Micro testing for possible contaminants

- Another for identity and assay testing to confirm potency and purity

We also retain another two samples, one for retention and another which we use for own 'in house' ID testing below.

PHOTO OF THE SAMPLES

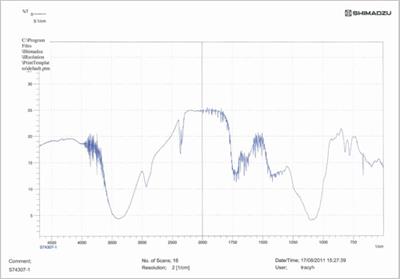

This is the machine we use when doing some of our 'in house' testing

PHOTO OF THE FTIR MACHINE

This is what the print out for the ingredient ID looks like.

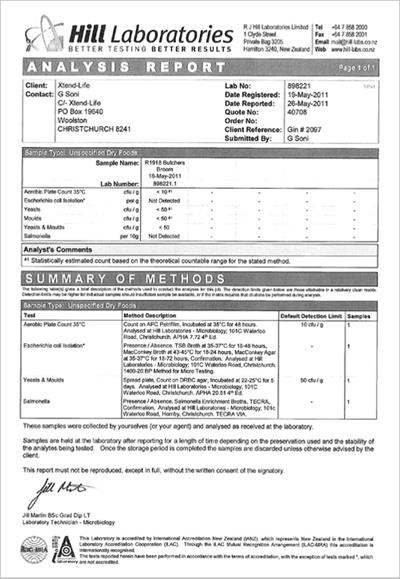

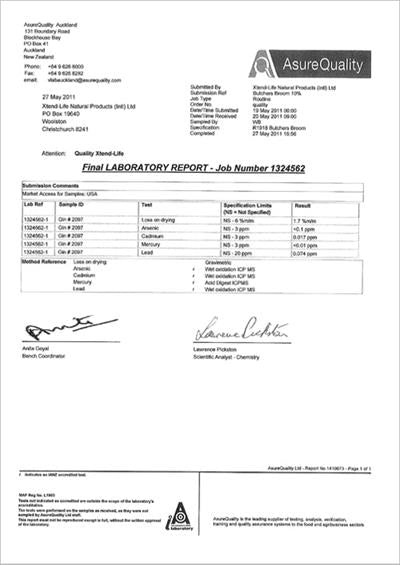

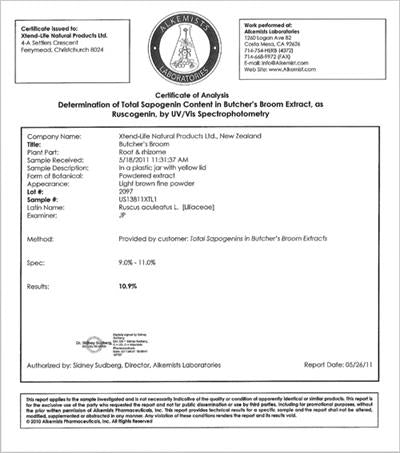

The following are examples of the microbiological test, heavy metal tests and assay tests.

MICRO REPORT - BUTCHER'S BROOM

HEAVY METAL REPORT - BUTCHER'S BROOM

ASSAY TEST REPORT - BUTCHER'S BROOM

The above explains the process that each ingredient goes through before it can be released into the production process.

In the next post I will go through the next step which prepares the blend for tableting.

Supplements

Supplements Bundles

Bundles